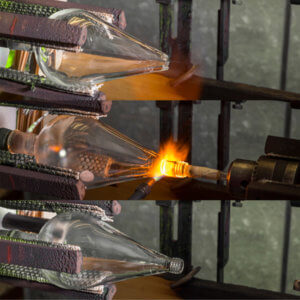

Auto-Lathe

Several of the glass processes can be fabricated with computer-controlled lathes which allows an operator to run multiple machines. Use of auto-lathes increases repeatability and helps ensure the consistency and accuracy of tolerances. Auto lathes are very useful when quantities are substantially higher and repeatability of dimensions is required.

Precision Bore Vacuum Forming

Also included on our production staff is the vacuum forming department. Using our proprietary process, inside diameters can be formed to very tight tolerances within +/-.0001″. Tapers, flats, multiple diameters etc. can be included with the mandrel for an array of inside diameter profiles.

Grinding and Cutting

The grinding department performs an array of functions. Precision cutting with diamond blades, cutting angles, drilling, beveling, countersinking, concentric grinding, centerless grinding, plunge grinding, outside diameter polishing, grinding flat, lapping flat, and polishing flat are some of our capabilities.

Custom Glassware

Our seasoned team of engineers and glass blowers have extensive experience to design and fabricate glassware to meet your specific requirements. Glassware we custom fabricate include chromatography columns, concentrator tubes, condensers, manifolds, environmental-ware, reactors, funnels etc. If you have a design in mind or a blueprint, feel free to email us at quotes@astraglassinnov.com to get a quote.

Glassware Repair Services

Astraglass Innovations offers services to modify or repair broken glassware. Repairing broken glassware is a sustainable way to reuse glassware at a fraction of the price of a new glassware. Typical glassware repairs include reattaching new joints, healing cracks and dents, attaching sidearms, replacing stopcocks, etc. To get a cost estimate, email repairs@astraglassinnov.com with a list of broken glassware, what you want fixed or modified along with pictures of the parts. We will also let you know if the parts can be salvaged.